Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

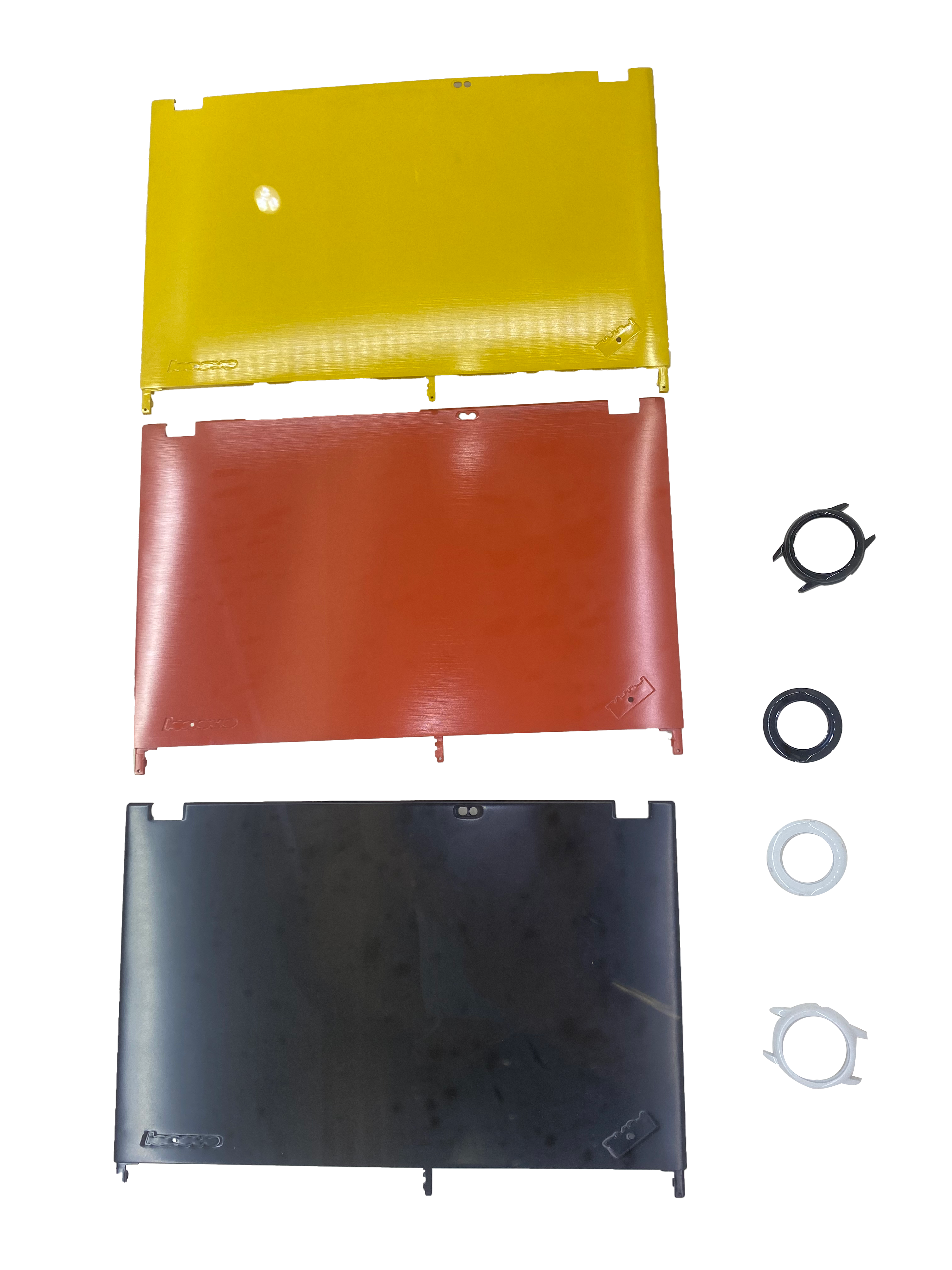

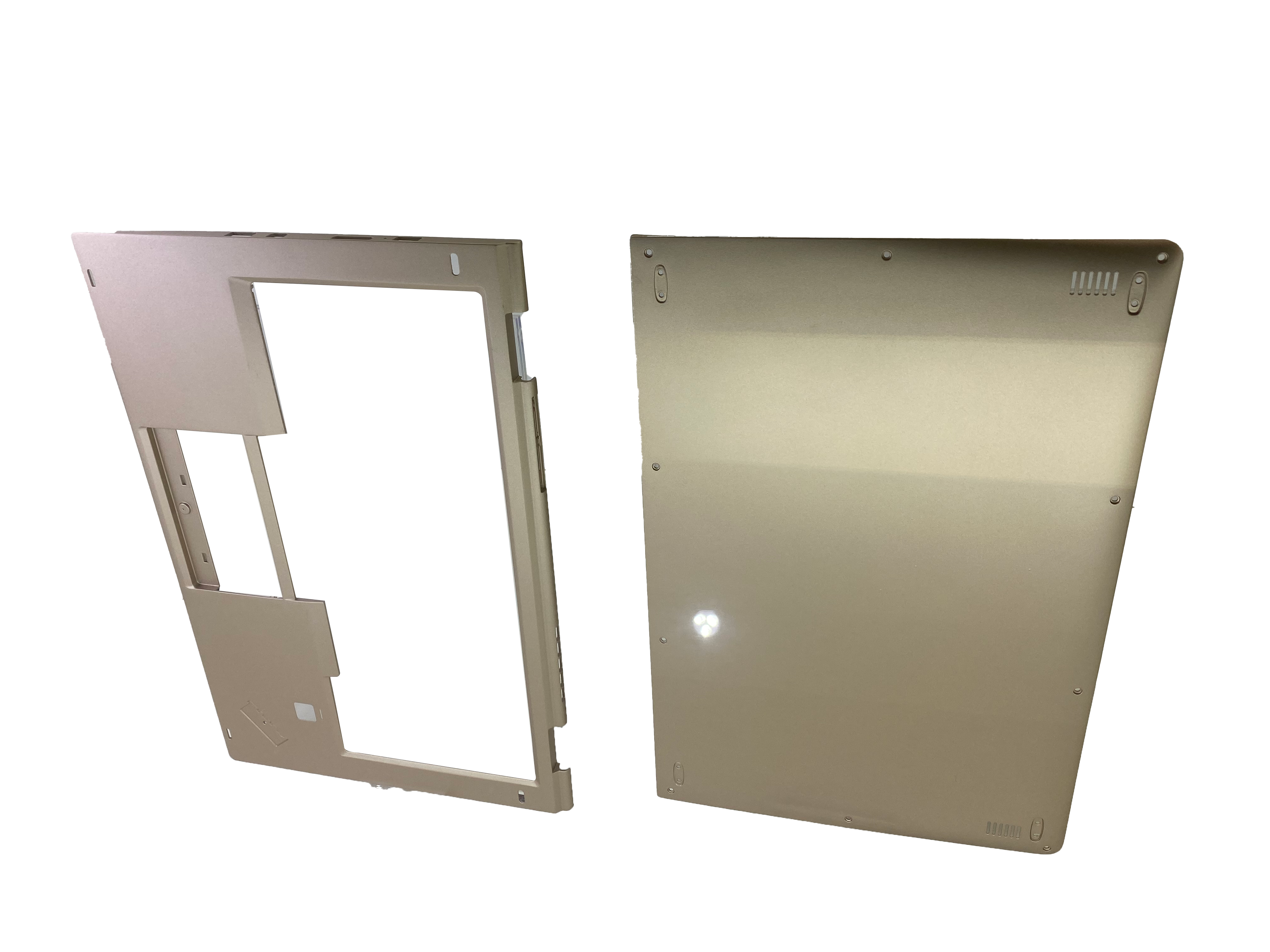

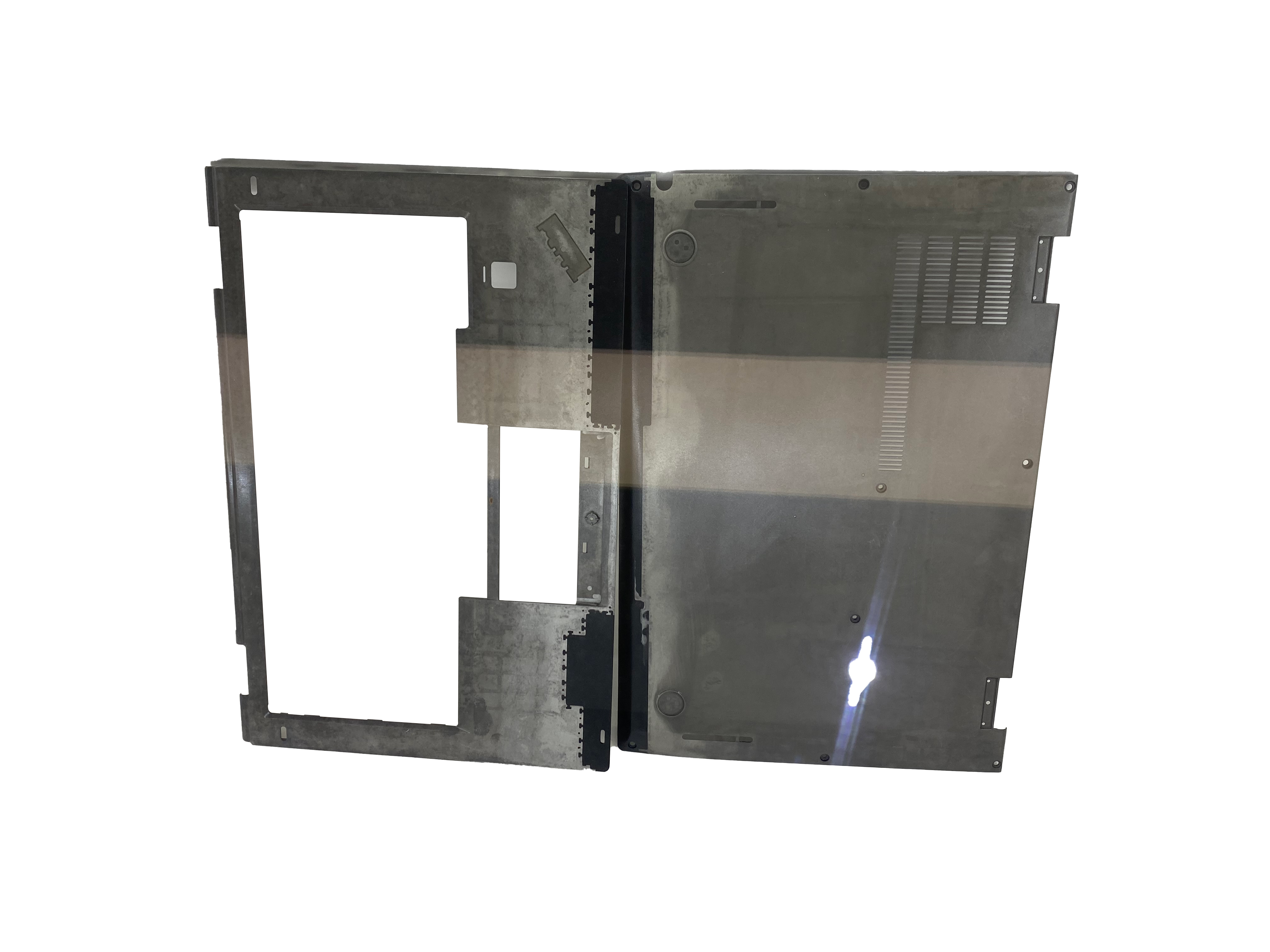

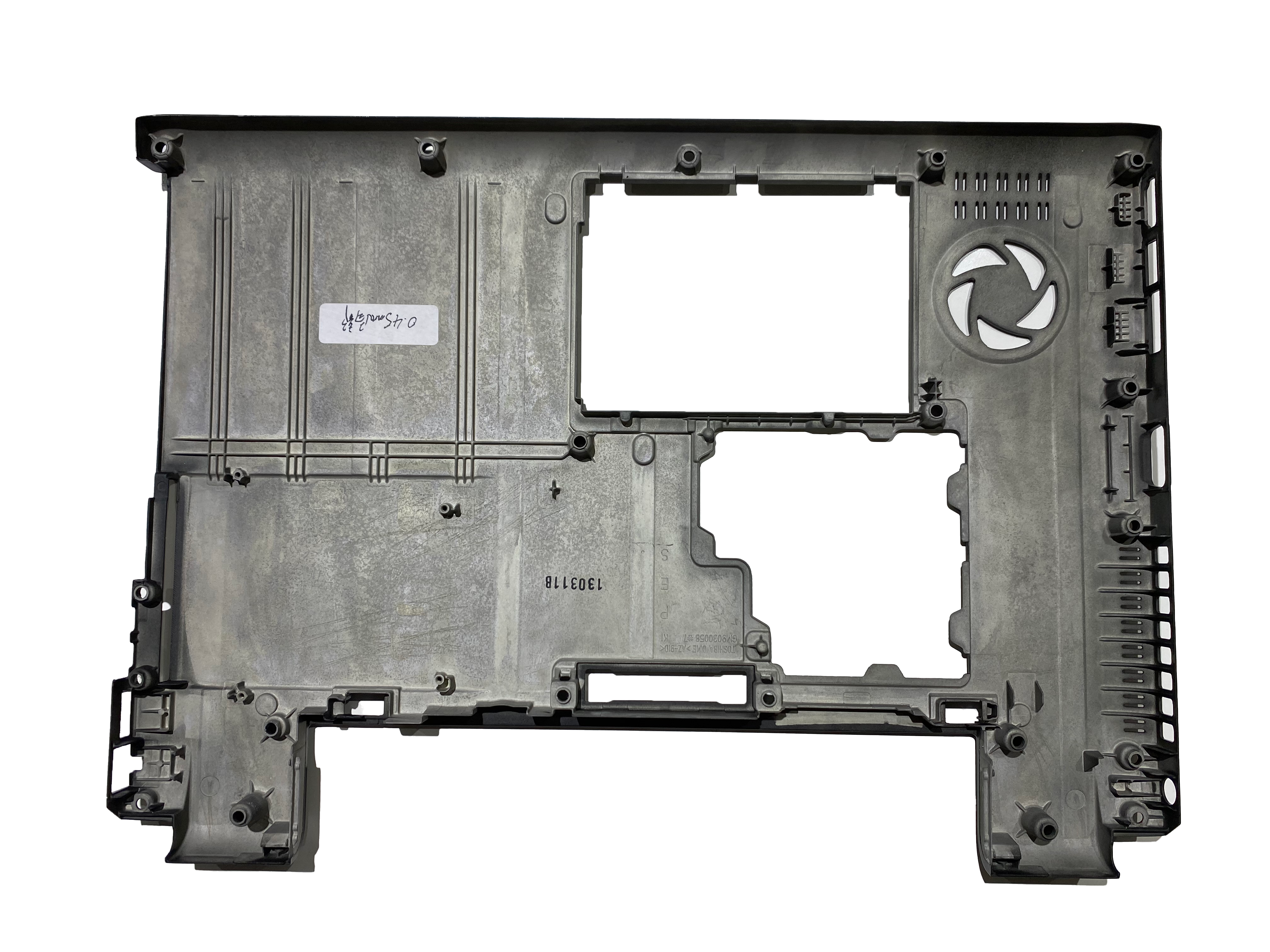

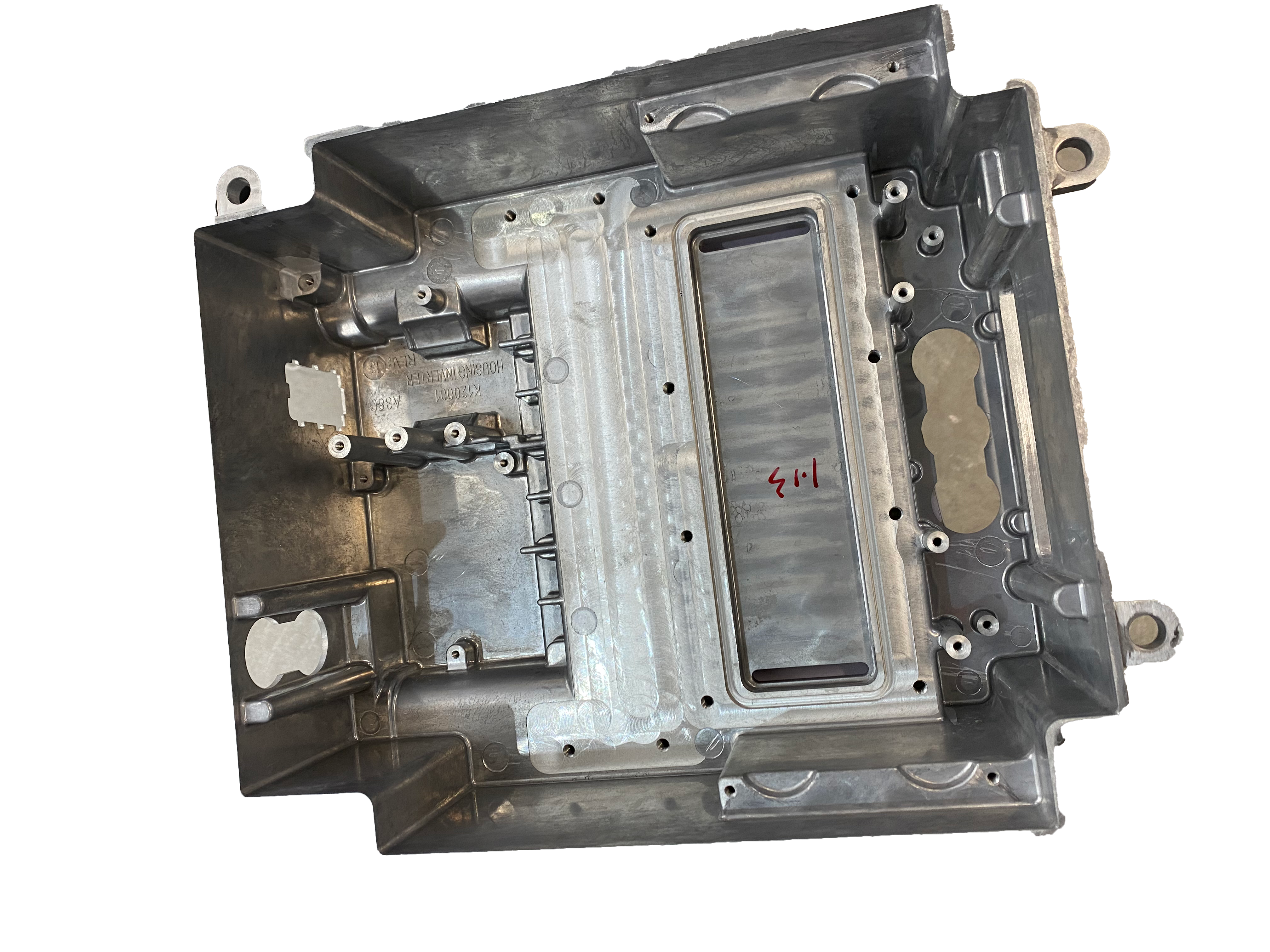

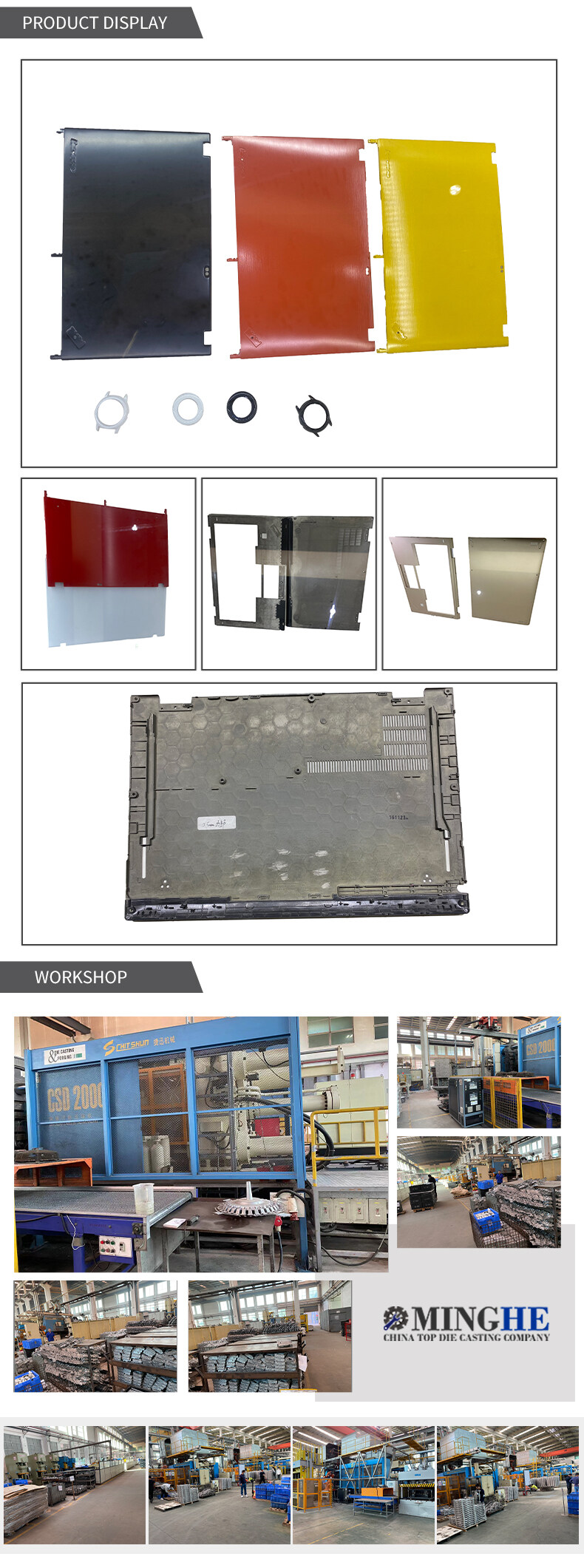

Precision Die casting parts

Similar to injection molding, aluminum high pressure die casting involves pouring molten cast metal into the mold chamber. Aluminum die casting services can be used to create intricate parts with intricate geometries. Automobile engine blocks, rocker arms, carburetors, water pump housing, gearbox housing, clutch housing, steering housing, and other production parts are among the precision die cast aluminum components.

Description of MINGHE Aluminum Die Casting

Aluminum is the most abundant metal element in the earth’s crust. It has good properties of malleability, flexibility, conductivity and durability. The surface is silver or dull gray. It’s a commonly used die casting material because of its excellent machinability. The die casting machine can manufacture unique and high quality batch aluminum prototypes parts. Die casting is just the perfect choice for the high precision of die casting aluminum. Aluminum high pressure die casting is putting molten cast aluminum in the mold cavity which is like injection molding. Complex parts with sophisticated shapes can be made through aluminum die casting service. The precision die casting aluminum parts contains: Automobile engine block, rocker arm, carburetor, water pump housing, gearbox housing, clutch housing, steering housing and other parts of the production and more.

Benefits & Features Of Die Casting Aluminum Material

Customization: It facilitates the attainment of complex designs and forms, making it easy to customize the casting to specific manufacturing processes.

Higher rates: Aluminum alloy die castings enable parts to be manufactured at a much higher rate than other metal alloys. Robotic die cast work cells are also used to increase production efficiency.

Lightweight strength: Aluminum castings offer the highly valued combination of light weight and superior strength.

Low cost: Aluminum die cast parts are cost efficient than other metal alloys.

Versatile and resistant to corrosion: Aluminum castings are extremely versatile and offer excellent resistance against corrosion.

FAQ

How to order?

First, Customer could send us your sample or drawing, such as 2D and 3D drawing(IGS or STP format). Second, Our engineers will check the drawing carefully and then provide you a better price. Thirdly, If you accept, then order confirmed.

Where is your factory?

Our factory located on Dongguan which is a beautiful city which is very near Guangzhou and Shenzhen. You can fly to Shenzhen Bao'an International Airport (ZGSZ) or Guangzhou Baiyun International Airport (ZGGG), we will pick you up at the airport.

Are you a factory or trade company?

We are a factory. We provide you one-stop service, from mold design to finish part.

How to ship?

The sample of die casting and CNC machining or small order is usually sent by TNT, FEDEX, UPS etc, and the big order is sent by air or sea after confirmation of clients.

What is your terms of payment ?

Die casting mould payments: advanced payment 40% after contract signing;

The 60% balance will be paid after approval of mould by customer.

The payment term of die casting orders: T/T, 30% as deposit be paid before production by T/T, 70% be paid before delivery.